Denim Manufacturers - An Overview

Get premium denim apparels from industry’s leading denim manufacturers focused on quality and sustainability as denim has been a fashion favourite for ages and will continue to be for years. From Millennials to Gen Z , people from different generations consider denim the fashion staple in their wardrobes. Whether monogram or embroidered patterns, denim has always been a versatile fabric. But the fabric is in trend right now as fashion enthusiasts constantly experiment with it and invent new ways to style it. Another reason Denim is a popular choice is the vast number of styles and designs available nowadays you can find any jeans you want. And not just jeans, several apparel pieces like denim jackets and denim shorts are acing the fashion world. And also as a leading denim manufacturers and apparel vendors in the USA, Pearl Global is making an amazing impact environmentally with the products which are made of environment friendly materials.

Even today, mannequins and models adorn most chiqué designs. Their chances of being enlivened in rich indigo hues are pretty good, thanks to denim. Be it the intricate detailed embroidered fashion, a specialized technique like jacquard, or just a basic stonewash effect, one clear thing is that you cannot go wrong with denim. This fabric has undergone a metamorphosis and has remained a staple to women’s and men’s wardrobes, transcending generations of designs and trends.

Denim is the most beautiful and easy yet interestingly innovative silhouette ever. Mix and match with a belt, a corset, and a loosely fitted jumper, and you’re good to go. This mix-and-match helps denim manufacturers play flexibly and experiment in the vast space. After all, production and manufacturing are where it all begins! They can easily go on to make bold statement looks that are almost always mesmerizing and catchy or add a tinge of shades or ripped designs, thanks to the world-class designers involved!

Which Place Is The Best For Denim Manufacturers And Why?

The Bangladeshi denim manufacturers industry has been flourishing tremendously recently, with significant manufacturing companies like Pearl Global establishing a stronghold. This has enabled Bangladesh to outrank China in supplying denim to Europe and the US: its primary export markets. As a result, many international brands are now drawn to the country’s denim industry, making it one of the biggest in the world to produce 180 million pieces of jeans annually. However, Bangladesh’s success in the sector is mainly ascribed to its extensive manufacturing capabilities and affordable production cost. Pearl Global is also standing out as one of the most reliable denim and sportswear manufacturers worldwide with the help of manufacturing facility based in Vietnam and India.

Apart from being leading apparel manufacturers in USA market, Bangladesh as a denim manufacturer and producer, holds the third largest market share of another one of the largest markets in the world, i.e., the USA at 14.2%. These numbers should be familiar given the significant investments being made in the industry in Bangladesh, pushing up its production capacity to its current capacity.

Moreover, globalization in recent decades has further accentuated Bangladesh’s denim industry’s growth and development, helping it flourish. Studies suggest industrialization will sharply push this production eastward over the next decade. Moreover, when R&D and the strengthening of supply chains came into play, the local industry boomed even more, making Bangladesh the go-to manufacturing destination for almost every top fashion house worldwide.

Denim Manufacturing At Pearl Global

At Pearl Global, we consistently believe in refining our craft and have created top-notch apparel for brands worldwide, thanks to our decades of experience in the manufacturing industry. We have a diverse portfolio with clothing options for people of all ages, sizes, and genders that we’ve created with passion and integrity. In addition, we firmly believe in providing sustainable apparels and environment-friendly fashion. Our co-creation process for apparel design that deals in denim brings about a comprehensive product portfolio. As denim manufacturers, our product offerings include jackets, shackets, shirts, blouses, dresses, all-overs, dungarees, trousers, shorts, skirts, etc.

We are a top denim manufacturer in USA, specializes in custom denim jeans with premium fabrics, sustainable production, and expert craftsmanship. We provide tailored solutions, ethical sourcing, and scalable production to meet your brand’s needs. As a trusted partner, we ensure high-quality, stylish, and durable denim that aligns with market demands.

Quality Control Steps Are Taken Care Of For Denim Manufacturing At Pearl Global

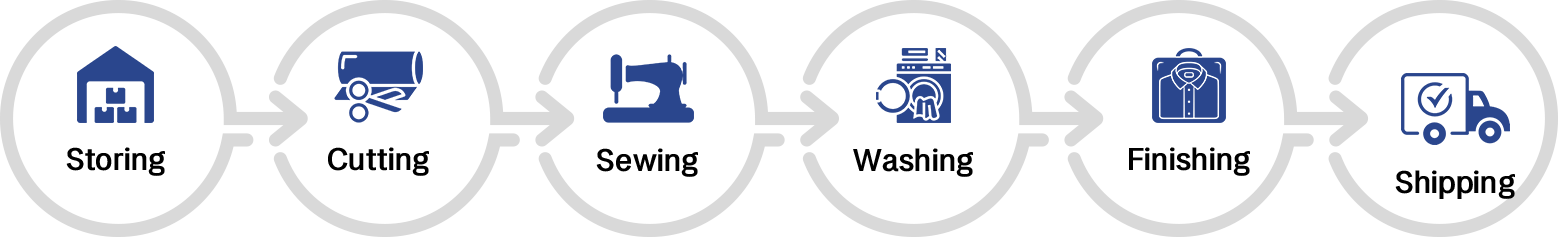

Let us first look into the services, stepwise, that you get with Norp Industries

The Quality Management You Get With Norp Knit Industries

Denim Manufacturing Unit Of Pearl Global In Bangladesh

Norp Knit Industries has established a quality management system (QMS) that they use for production that’s taken cognizance of very closely at regular intervals. It is taken care of regularly to ensure quality and safety at the workplace where denim is manufactured through quality control and all the stated procedures, bearing in mind the legal terms. Factors taken care of are our data analysis, quality analysis, and objectives assessment. This is made possible through quality policies and procedures. In addition, corrective and preventive measures, along with all the steps mentioned above, are also often taken.

Fabric Warehouse

- Each fabric identifies FIFO (First in, first out) sticker & bin card.

- 10% fabrics visual inspection of each lot & each colour.

- Making before-wash & after-wash blankets with 100% shade segregation to prepare colour continuity cards for customer approval.

- 100% rolls shrinkage test and pattern grouping based on the shrinkage.

- Skewness test and GSM test verification per lot.

- CSV test to avoid parts shading.

- A dehumidifying machine and temperature & humidity meter are installed in the storage area to maintain humidity below 60%. Temperature and humidity are checked and recorded three times a day.

Trims & Accessories

- Each fabric identifies FIFO (First in, first out) sticker & bin card.

- 10% of the visual inspection is devoted to trims and accessories.

- Home laundry tests are conducted on all trims to ensure colour fastness.

- A dehumidifying machine and temperature & humidity meter are installed in the storage area to maintain humidity below 60%. Temperature and humidity are checked and recorded three times a day.

- As per customer requirements, the QA team inspects 10% of the incoming trims & accessories for mould, moisture & musky smell.

R&D

- Risk assessment, PP meeting, size set and pilot run process to identify possible risks with a preventive and corrective action plan.

Cutting Floor

- 100% shrinkage added computerized marker utilized for bulk cutting.

- Lycra fabrics are relaxed for a minimum of 48 hours, and cotton fabrics for a minimum of 24 hours.

- 100% panel checking procedure to avoid rejection.

- A temperature & humidity meter is installed in the cutting area. The temperature and humidity are kept in check thrice a day.

- 10% cutting roll mould, moisture & musky smell must all be checked with proper records.

Sewing Floor

- Upgrade automatic sewing machine (Auto pocket setter, Pocket rolling, Pocket decoration, Elastic joint & cutting, Semi-Automatic bottom hem, APW (Automatic pocket welt), Loop setter etc.)

- Needle point control procedure by the QA team.

- 100% quality control process inline & end line.

- Special shade identification label used in the manufacturing process.

- AQL -1.5, level –II lot audit manufacturing goods.

- A temperature & humidity meter is installed in the production area. A proper record of the temperature and humidity is maintained thrice a day.

Washing

- All our machinery is sustainable and eco-friendly.

- Before washing, 100% shade-wise segregation procedure for denim products.

- ZDC level -3 chemicals are used in the washing plant.

- Each process our QA team verify (Shade, hand feel, measurement etc.)

- In-house accreditation laboratory. Accredited by (Target Australia, Kohl’s, Tommy Hilfiger & Next)

- We perform a plethora of tests ( pH, colour fastness to rubbing, GSM test, shrinkage test, colour fastness to washing, colour fastness to corking, colour fastness to water, colour fastness to perspiration, colour fastness to saliva, colour fastness to phenolic yellowing, colour fastness to light, dimensional stability to washing, general appearance after a wash, determination of twisting/spirality, appearance after Home Laundry, Pilling Resistance (ICI), Seam Bursting/Bursting Strength, Tear Strength, Tensile Strength & Seam Slippage)

- A temperature & humidity meter is installed through the washing plant and is checked properly thrice a day.

Finishing & Packing Area

- 100% shade segregation as per customer requirement.

- Ensuring workmanship and measurement standards as per customer requirements.

- 100% product scan through a metal detector to ensure product safety.

- AQL-1.5, level -II audits to ensure the customer requirement.

- All finished product lot-wise mould & moisture tested by the Aqua boy moisture meter.

- Delegated humidity room to control mould & moisture.

- A temperature & humidity meter is installed through the finishing and packing area and is checked properly thrice daily.

- Finish goods inspection procedure; delegated denim specialist QA team will perform an overall inspection to ensure hand feel, shade, quality, measurement & packing etc.

Finished Goods Warehouse

- A dehumidifying machine and temperature & humidity meter are installed through the storage area to maintain humidity below 60%.

- Plastic plates are used in the finished goods warehouse to keep the carton.

- Distance between the wall and carton storage above 150cm.

As leading global bulk clothing suppliers and apparel manufacturers, we’re focused on improving quality while reducing costs and ensuring the safety of products and their legality. This is done by establishing the highest quality procedures based on international standards to attain the utmost consumer satisfaction.

How To Avail Services By Pearl Global Denim Manufacturing?

To avail of our global denim manufacturing services, connect with our marketing team at vikas.mehra@norpknit.com